Facade Insulation

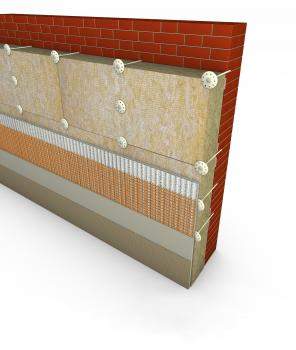

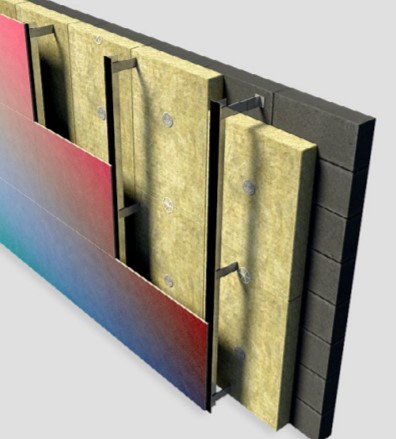

Facade Insulation involves the installation of an insulating layer to the external fabric of an existing, or new building, and is usually finished with a render and painting, or cladding, or rainscreen facade system. External wall insulation solution depends on the level of thermal performance to be achieved, which finish is the most suitable and the Reaction to Fire classification of the insulation. Using a breathable mineral rock wool solution allows moisture vapour to pass through the construction to outside, removing the risk of condensation. Rock wool is non-combustible and have the best possible A1 Euroclass Reaction to Fire classification.

New solid walls should prevent moisture ingress arising from exposure to rain and snow without moisture penetrating to the inside and damaging the building. The most important issue to be considered is the level of thermal performance to be achieved, the insulation type and which finish is the most suitable. Particular attention will need to be made to window sills, jambs, rainwater goods and the roof eaves as structural changes may be required to accommodate the thickness of the external wall insulation system.

The best facade insulation solutions are usually comprised of rock mineral wool or expanded polystyrene (EPS). Both rock mineral wool and EPS boards have excellent thermal insulation performance, whilst rock mineral wool products are non combustible which negates the need to install fire barriers and EPS has the advantage of being lightweight.

An external wall insulation can deliver an airtight structure and reduce draughts and heat loss as any cracks and gaps in the external fabric of the building will be covered and sealed by the system. An excessive air leakage which, if not treated, can lead to high energy costs, occupant discomfort from draughts and external noise, as well as a reduction in indoor air quality.

An external wall insulation system prevents interstitial condensation from forming because the dew point temperature is moved closer to the external face of the insulated structure. Interstitial condensation occurs when warm, moist air from inside a building penetrates into the fabric of a structure and meets a cold surface, where it cools, reducing its ability to carry water vapour and increasing the risk of condensation forming within the construction. A vapour permeable insulation product can further reduce the risk of condensation forming as it will offer negligible resistance to the passage of water vapour and in effect allows the wall to breathe. It should be used in conjunction with a vapour permeable render coat. Surface condensation thus is prevented from forming on internal wall surfaces. Overlaying the existing thermal bridges with insulation removes any significant thermal bridging, reducing the heat loss and prevents condensation from forming.