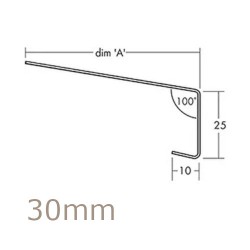

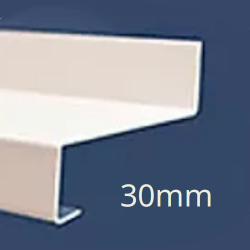

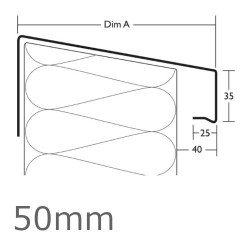

Sill Extensions and Flashings

Protecting against air and water leakage through the windows requires careful detailing. Window failures through water intrusion result in indoor air quality issues to structural problems. Proper sill flashing will protect the wall and drain water away. The sill is your last line of defence against future big problems. Once the window is installed, a back dam has to be created with a continuous bead of sealant along the window frame and the sill to block any incidental water that may intrude in.

The primary purpose of flashing under sills is to protect the wall below. If there is a moisture penetration problem, it is easier and cheaper to repair a sill than to repair the wall. In general, whenever flashing is installed in a wall, weep vents have to be created.. Without weeps, water may become trapped behind or under the sill, which could eventually enter the building or deteriorate the mortar and/or sill through freeze thaw cycles.

Extreme care should be taken to prevent sags, which may collect water and eventually leak into the wall insulation system or building. You should use rigid flashings, which are available online from facadeshop at competitive prices.

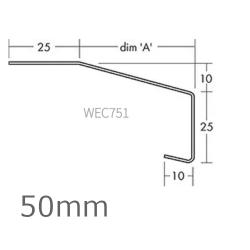

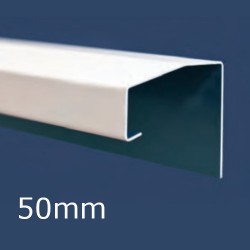

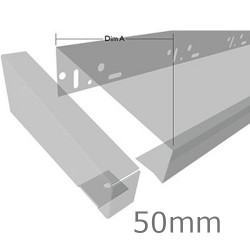

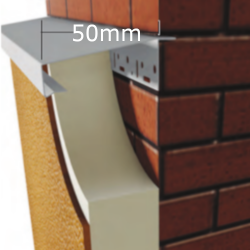

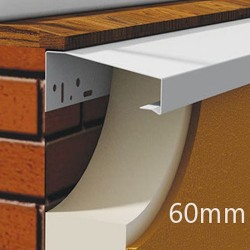

The Over Sill Flashing is designed to extend the length of an existing window sill, so that it overhangs the insulation. The purpose of this is to prevent water ingress behind the insulation, and to prevent serious damage to the insulation.

Over sill flashings and under sill flashings are used on top and the bottom of window openings and other openings to stop the rain water from directly attacking the insulation and render.

Aluminium Verge profiles are designed to protect the system on gable ends and roof lines. Eaves Flashings are used on the overhang and at the edge of the roof to protect the facade from adverse weather conditions. They create a roof drip edge that helps channel water into a gutter or away from the facade.

Usually avaiable in Aluminium White Coated with peel-off low tack film to protect the section during transportation and fixing on-site. Jointing clips can be supplied to retain the projecting nose of the section if required. Larger sizes or variations on any of these profiles can be manufactured to your specification, and powder coated to any standard RAL colour.