Beads, Tracks and Profiles

Types of Beads, Tracks and Profiles

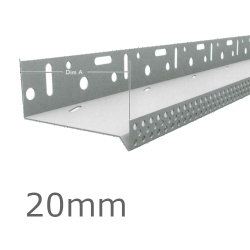

- Base tracks,

- Stop Beads,

- Corner profiles,

- Frameseal beads,

- Render stop beads,

- Movement beads,

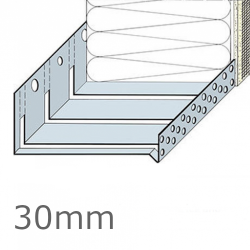

- Expansion beads,

- Bellcast beads

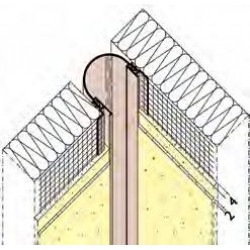

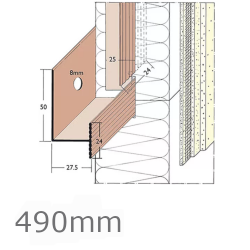

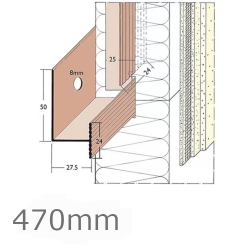

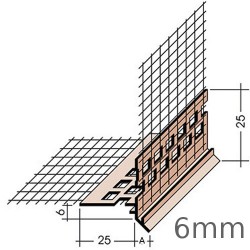

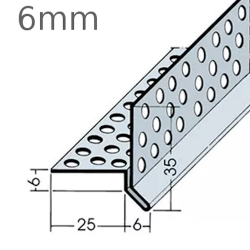

Aluminium Base tracks usually has a box profile and holds the external insulation perfectly. They are available in standard widths to match the width of the insulation boards. They can be interconnected lengthwise using matching PVC clips. Base tracks are fixed along the top of the damp proof course. PVC clips with mesh can be mounted on the edge of the base track - mesh to hold render over the insulation layer. These PVC clips have an angled drip edge. Base tracks are also available in galvanised steel and stainless steel.

- Bridging the damp proof course with base track fixings should be avoided.

- Avoid small cuts and always allow for a 2mm gap between sections to accommodate thermal expansion.

- Any gaps between the substrate and the base track should be packed out with mortar or suitable sealant to level the track and to prevent any future system failure.

- Avoid warping the base track by fixing into an uneven wall surface.

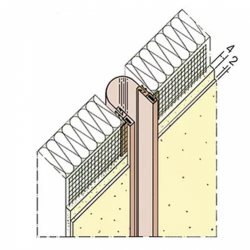

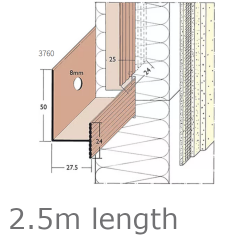

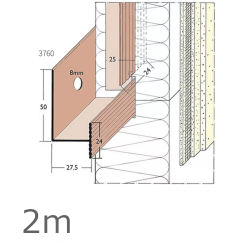

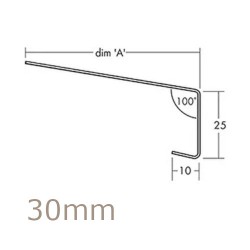

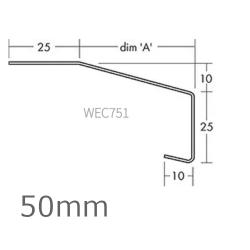

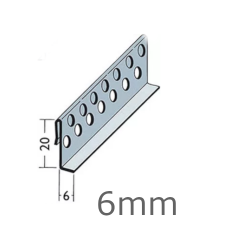

Aluminium Stop tracks and stop beads are used at the end of external insulation and render systems. The Stop tracks and beads are affixed vertically along a wall boundary and around openings such as doors, windows or pipework.

Rendering is helped by a broad assortment of PVC profiles for external wall insulation systems: PVC clips and profiles with mesh, stop beads, corner beads, movement beads, expansion beads and drip beads.

Stop beads can be used in dividing the wall surface into sections, along a wall boundary and around openings such as doors, windows or to create a break of work to be completed in sections. Stop beads may also come with attached mesh.

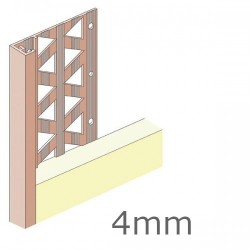

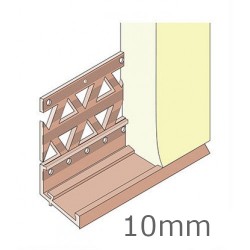

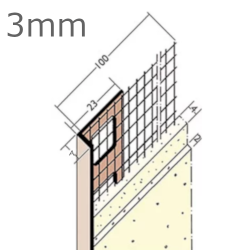

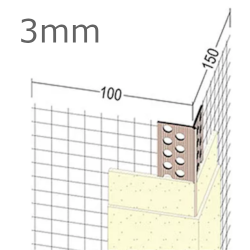

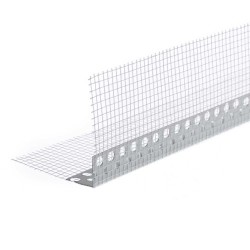

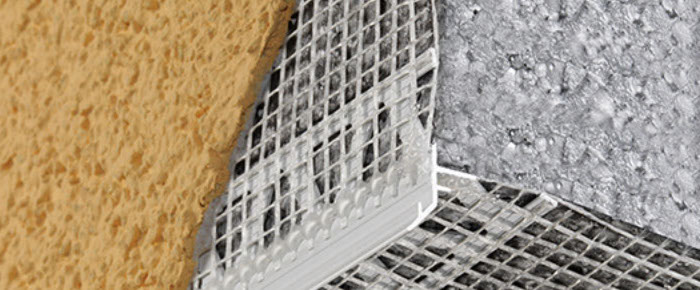

Corner beads are used to create a straight edge at wall corners and in reveals, and available with or without a detachable plastic nose.

Mesh wing corner beads are used where corners or reveals are to be formed without a protruding edge. The fibreglass mesh wing will be completely embedded into the render for maximum strength on system stress points.

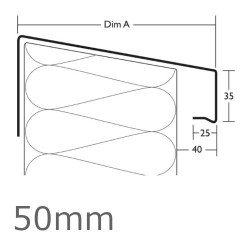

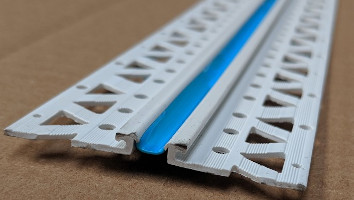

Movement beads are used to express movement joints in the substrate. They can also be used to break up large panel sizes and to indicate the boundary lines of attached properties. The expansion joints shouldn't be covered with insulation.

When the structure expands, the Expansion joint profiles and corner expansion joint profiles allow the external insulation and render systems to move elastically.